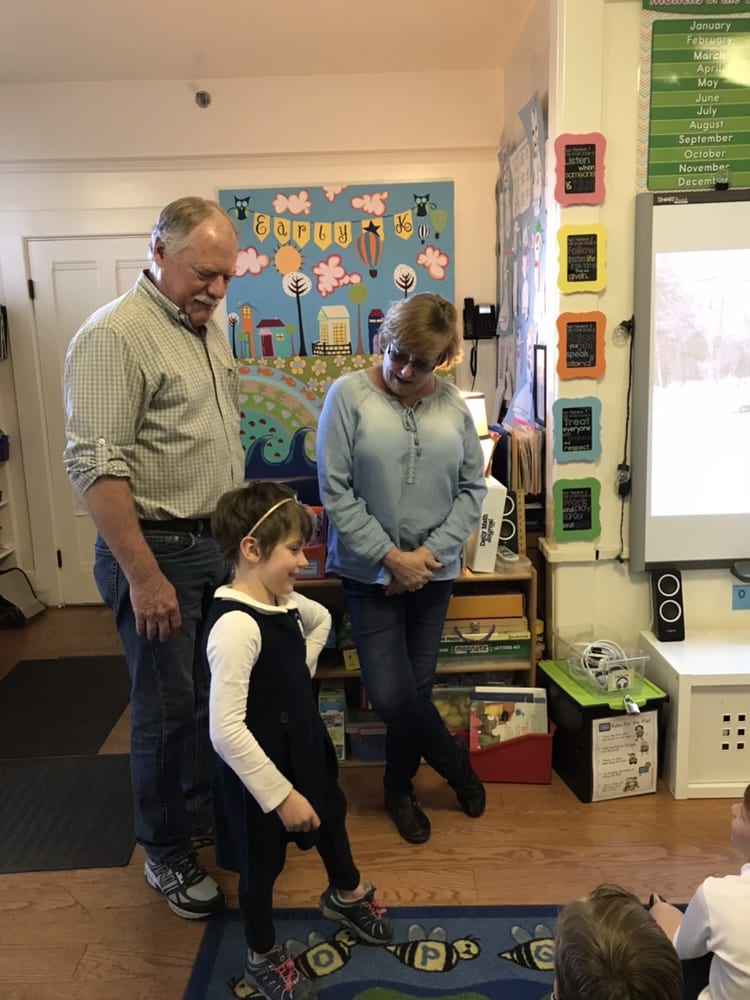

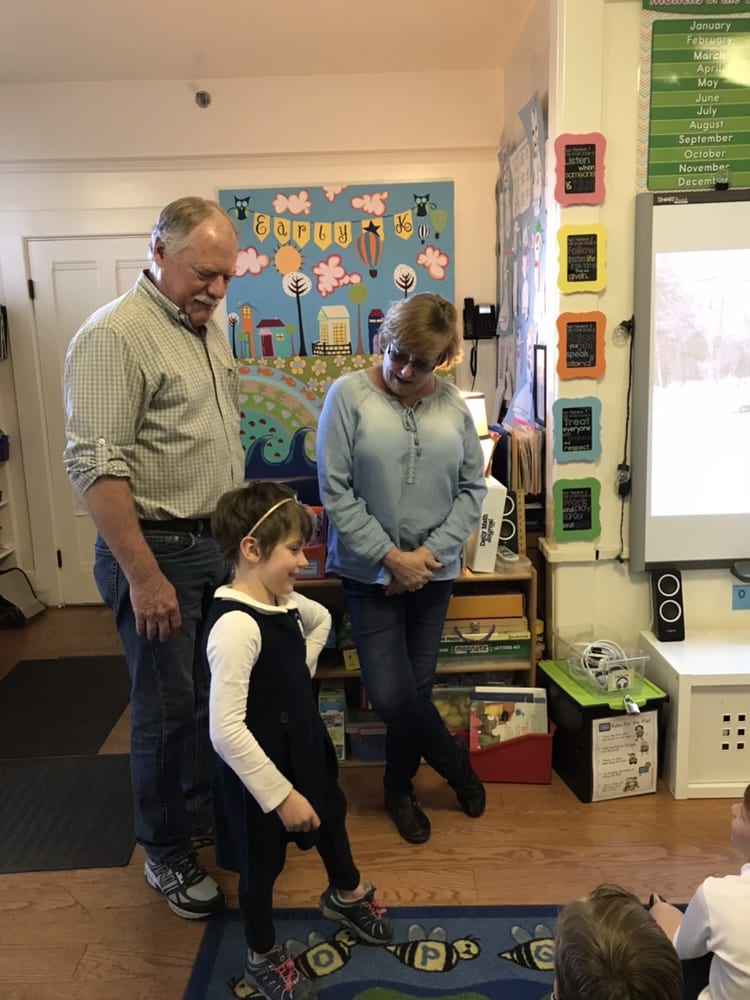

We had some very special visitors come to our class on Thursday afternoon. River’s grandparents joined us to talk about a very unique hobby they both enjoy (and we got to enjoy the sweet outcome!).

Harvesting maple sap to make maple syrup!

I am honored to have the Markstrums contribute to this blog post:

Making Maple Syrup

Maple syrup is made in the northern zones of the country where it is cold, and snow remains on the ground through most of the winter. In the spring when temperatures begin to rise above freezing during the day, maple trees start to wake up, and the sap begins to flow. Usually, this occurs in late February through March and into April. Ideal conditions are snow on the ground with daytime temperatures above 32 degrees and nighttime temps below freezing.

To collect the sap a small hole is drilled about 2 inches into the tree, a metal spout is gently tapped into the hole, and a pail or plastic sack is hung on the spout to catch the sap. Depending on how active the trees are the sap is collected every two or three days. Early in the season sugar content is high, so it takes on average 40 gallons of sap to make one gallon of syrup. Later in the season, the sugar content goes down so it may take almost 50 gallons to make one gallon of syrup. We used about 900 gallons of sap to make 19 gallons of syrup. Once the trees begin to sprout leaves, the sap becomes discolored and the season is done.

Most small producers like us boil the sap down in a metal pan over a wood fire and finish it in a kettle on the kitchen stove. Larger producers use big evaporation units and make thousands of gallons that are sold commercially. You have to cook it until the sugar content is at least 66.5% but not higher than 67.5%. Too low the syrup will be thin and watery and above that the syrup will be too thick and the sugar begins to form crystals. As the syrup is close to being finished, it is measured with a hydrometer to assure the sugar content is correct and ready to bottle.

Once it is ready to bottle, the boiling syrup is poured through felt or filters to remove the fine sugar sand from the syrup. The hot syrup is then poured in sterile jars, capped and allowed to cool. The sealed jars can be stored at room temperatures on the shelf for a long time. Once the jars are opened the remaining syrup should then be refrigerated.